Customized pressure sensors for peristaltic pumps

The application:

In some applications the pressure needs to be measured without getting in direct contact with the media for hygienic reasons. This is the case in a peristaltic pump for example. In this special application the pressure is measured in the tube, sometimes with a disposable for the separation of the pressure sensor from the media. Further requirement could be, that cleaning and sterilization should be avoided, no medium should leak out and the hose should be easy to replace.

One field of such an application are medical devices, e.g. peristaltic pumps, in which the medium to be pumped is forced through a hose by external mechanical deformation.

The challenge:

- Easy integration in the respective application of the user

- No contamination of the medium in the pump under any circumstances (hygienic design)

- Precise measurement to detect even the smallest deviations (As the piece of hose to which the pressure sensor is attached must be flexible, there may be minimal changes in diameter.)

- High overload resistance required for the regular change process of the pump tube

Our solution:

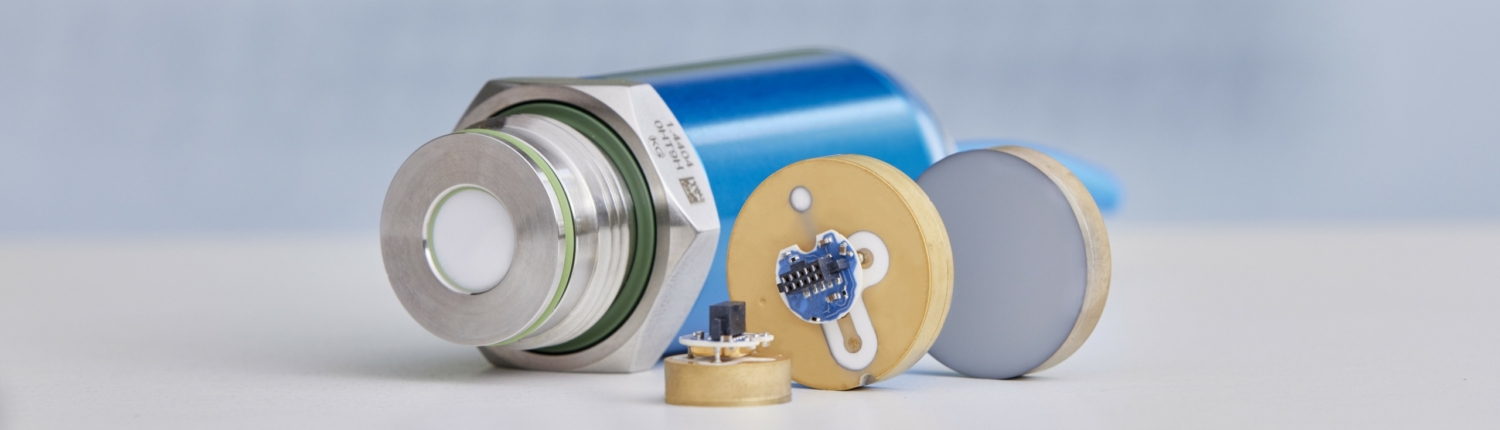

In the application of pressure measurement in a hose, the sensor monitors the pressure with which the loop is compressed. Endress+Hauser Sensors&Components recommends a flush mounted ceramic transducer with hygienic housing made of stainless steel for this purpose, as it prevents deposits. The membrane of the pressure sensor is made of high-purity ceramic and therefore highly resistant.

Endress+Hauser Sensors&Components has been developing customer-specific sensors for over three decades and focus the activities on partnership-based collaboration with customers. An interdisciplinary team from development, product management and sales handle implementing the users’ requirements in the best viable way.

All information to the capacitive-ceramic pressure portfolio can be found on the corresponding product page.