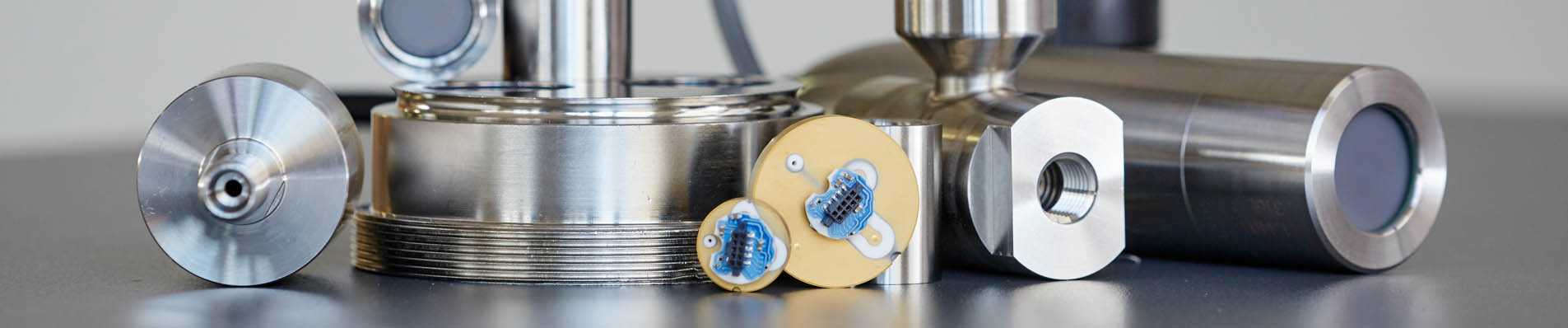

Ceracore technology

Our basic technology for your success

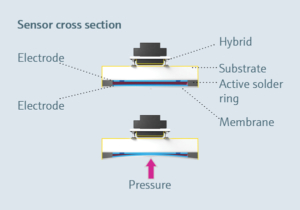

The Ceracore sensor is based on a capacitive measuring principle. In this case, the main body and membrane act as components of a capacitor. If pressure is applied to the sensor, the distance between the two electrodes changes due to the deflection of the membrane. This leads to a change in capacity, which is converted via the transmitter into an electrical output signal. Capacitive ceramic sensing technology offers a number of advantages.

Advantages of ceramic technology:

- Patented metallic active solder connection of sensor base element and membrane

- Metallic coating of the sensor base element for improved EMC compatibility and reduced installation sensitivity

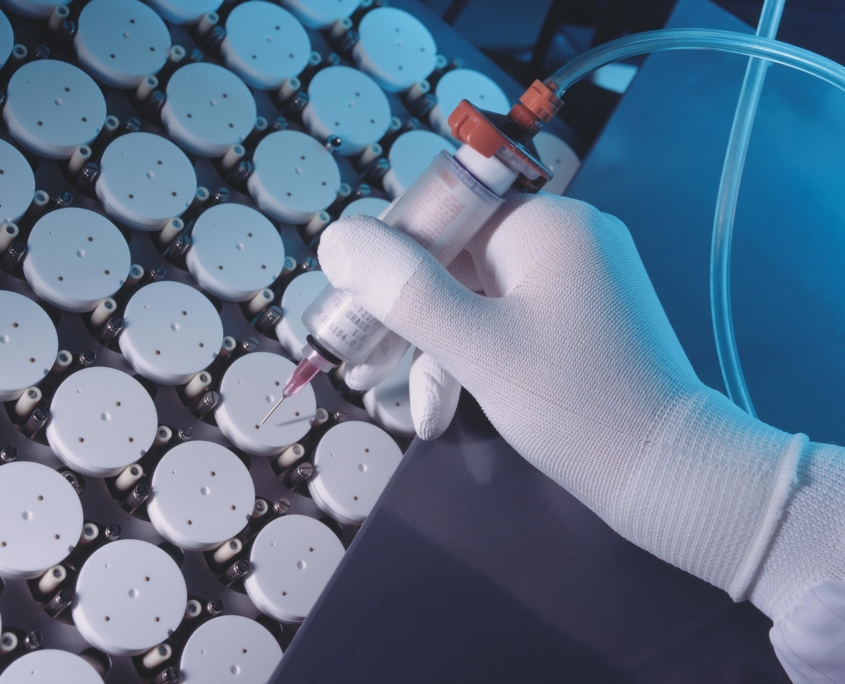

- Made of high-purity ceramic (99.9% Al2O3), highly resistant and chemically neutral to a wide range of process media

- As a dry measuring cell without the use of oils for pressure transmission, the Ceracore is absolutely vacuum-resistant

- Highest overload resistance

- High reference accuracy of 0.1%

Security:

- Self-monitored measuring cell for maximum safety

- Communication via secure protocols

- Improved EMC resistance (guarding)

- Approved z. Eg ATEX, …

- RoHS

- FDA listed materials

Application-specific configuration:

- Sensor pre-configured at the factory (damping, turn-down, measuring range, …)

- Adjustable measuring rate for optimal resolution / power consumption

- Customer-side configuration possible

- Output of the pressure and temperature signal possible

- Power consumption 2.5 to 10 mW

- Various sizes (diameter: 17.5 mm and 32.4 mm)

Communication:

- Analog output signal – voltage output ratiometric or voltage output absolute

- Digital output signal – SPI or UART interface

- Digital and analog output signal combinable

- switching output

- temperature output